Our Plastic Fuel Tanks are engineered with safety in mind

Fuel tanks are automotive parts which store gasoline. Fuel tanks are regarded as important safety-related parts, and Yachiyo develops fuel tanks by putting the top priority on customer’s safety, such as fuel containment not only during normal use, but also in case of automobile collisions.

Fuel tanks are automotive parts which store gasoline. Fuel tanks are regarded as important safety-related parts, and Yachiyo develops fuel tanks by putting the top priority on customer’s safety, such as fuel containment not only during normal use, but also in case of automobile collisions.

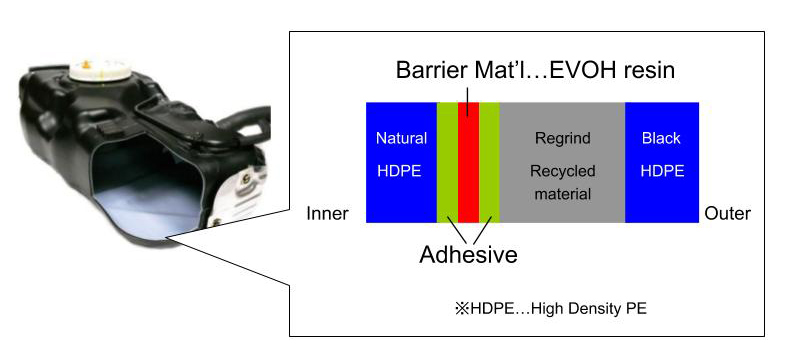

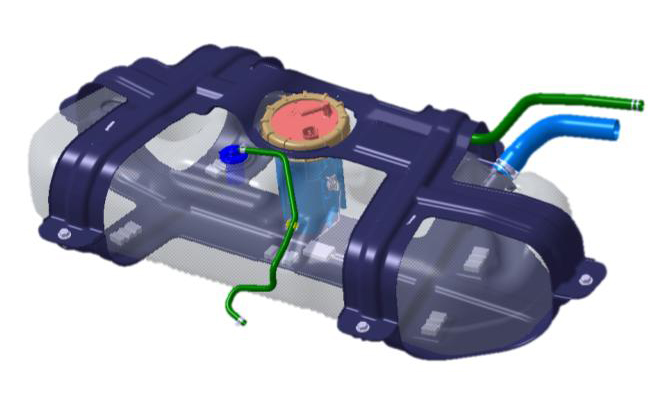

Yachiyo’s resin fuel tank is a “four-material six-layer” structure that consists of four layers of resin material in six layers which are blow molded.

It has earned high marks from the market with top-class safety and environmental performance.

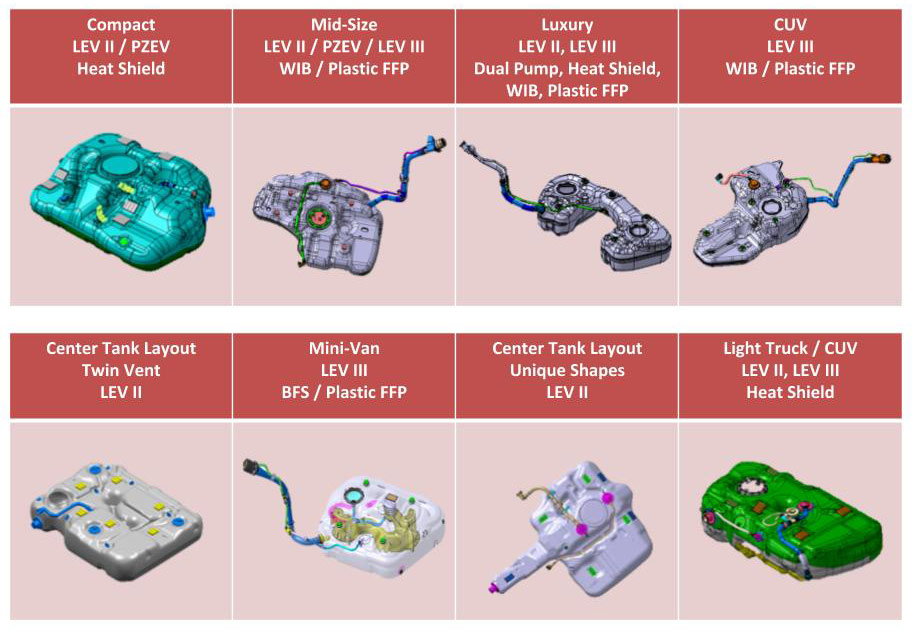

Along with the diversification of the environment and the layout, it is possible to design a lightweight shape with a higher degree of freedom compared with the conventional steel tank, making it the new mainstream of fuel tank technology.

Evolution of Fuel Tanks

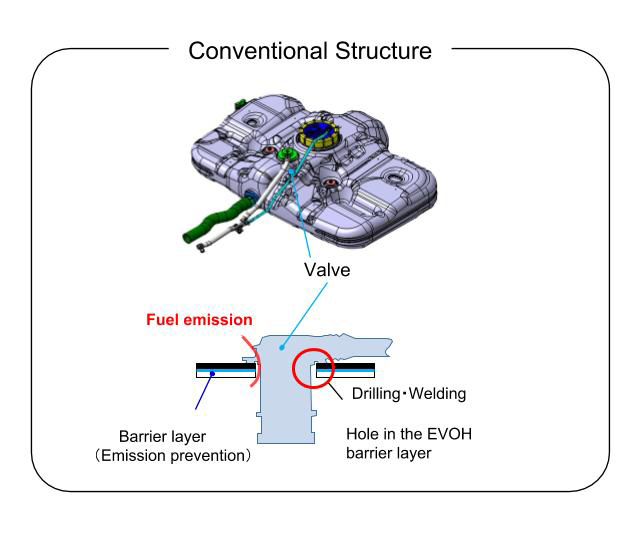

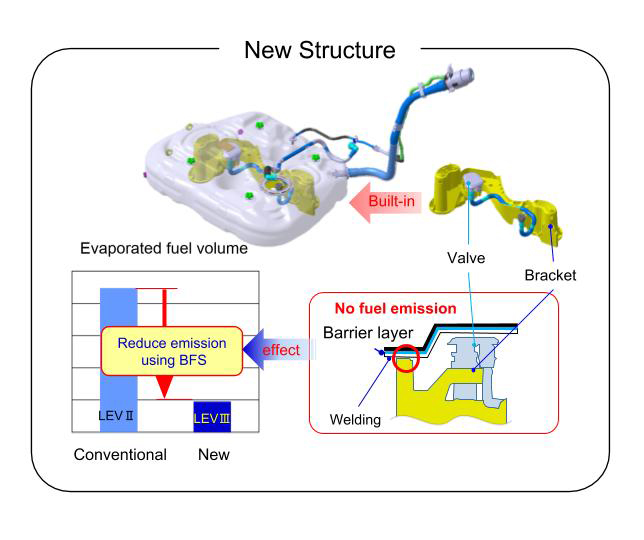

BFS technology that can meet strict environmental regulations

BFS: Built-in Fuel Tank System

Yachiyo improved functional parts by adding built-in technology that reduces fuel emissions by eliminating the drilled hole for valves. Instead, the valve is held by an internally welded bracket assembly.

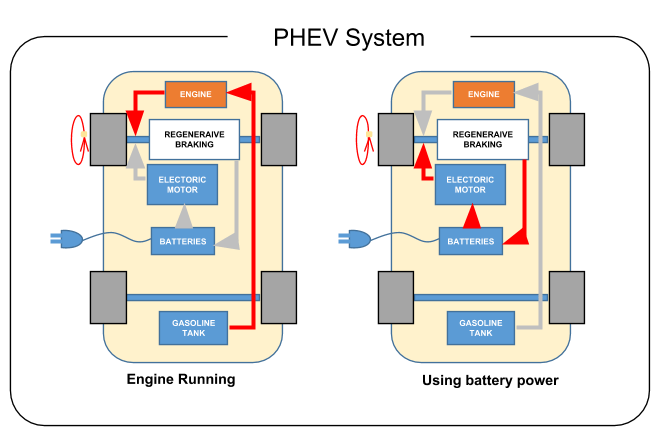

High pressure sealed plastic fuel tank—For PHEV development

PHEV: Plug-in Hybrid Electric Vehicles

Yachiyo is looking ahead to the expansion of PHEV associated with acceleration in electrification of vehicles. Our current focus is the development of a plastic fuel tank for PHEV.

Engine stops when vehicle

is on battery power

↓

Vaporizing fuel is trapped in the fuel tank

↓

Pressure in the tank rises

↓

Improved pressure resistance

of the fuel tank is required

Fuel Tank Development

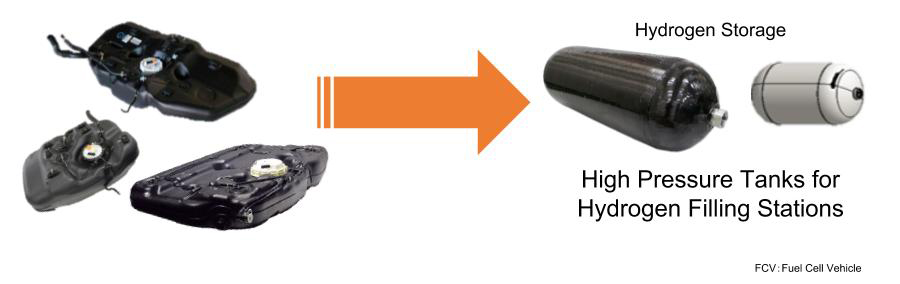

Efforts Toward a Hydrogen Society

Yachiyo is utilizing the technology and know-how cultivated from years of development and manufacturing of plastic fuel tanks for automobiles to also become an “Energy Storage Supplier” and manufacturer of devices to store various energy sources. Forefront among these efforts is the development of high pressure tanks for hydrogen storage stations and fuel cell vehicles.

Plastic Fuel Tanks

FCV Hydrogen Tanks